Problem

Youandafriendarehelpingtobuildahouseforyourdog,Ollie.Thewoodenboardsarecut.Theholesaredrilled.Allyouhavetodoisconnecttheboardstotheframe.Yougrabascrewdriverandsomescrewsandgoto work.

Thefirstturnofthescrewiseasyenough.Butthenitgetsharderandhardertoturn.Youholdthescrewdrivertighterandstraintoturnthescrew.Uhhhh! Grrrr!Afteraminuteofstruggling,thescrewisstillstickinghalfwayout.Ollietiltshishead.Hemustbewonderingifhisdoghousewilleverget finished.

Solution

Meanwhileyourfriendishavingamucheasiertime.Sheisalreadyputtinginherthirdscrew.“Hey,whyareyourscrewssoeasytoturn?”youaskwithatouchofjealousy.Shebeamsabigsmile.“IguessI’mjuststrongerthan you.”

“No,really.Our screwdriversarethesamesize.Theholesarethesamesize.Eventhescrewsarethesamesize.Sowhat’sthe difference?”

Thenyounoticeit.“Hey,lookatthis.Thethreadsare different.”

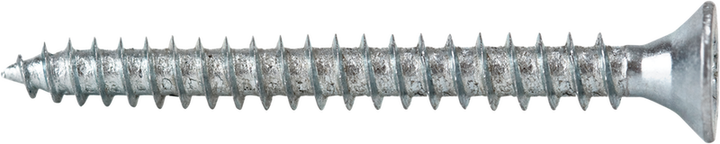

Theridges,orthreads,ofyourscrewaremuchfartherapartthanonthescrewsyourfriendisusing.Yourfriend’sscrewshavealotmorethreads,andtheyarereallyclosetogether.Thatmustbe it!

Youtryoneofthescrews.Youhavetoturnitalotmoretimes,buttheyareeasyturns.Thescrewgoesinfastandholdstheboardtighttotheframe.“That’smorelikeit!”youexclaim.“NowthatIhavetherighttools,we’llhavethisthingbuiltinno time.”

“AndIthinkOllieisgoingtolovehisnewhouse,”yourfriend adds.

Woof!Woof!Olliethinksso, too.

It's Simple

Whatmadethescrewssuchgoodtoolstoholdthewoodtogether?It’ssimple!Ascrewisasimplemachine.Likeallmachines,simplemachineshelpusdojobs,usuallybymovingthingsfaster,farther,ormoreeasilythanwecanwithoutthe machine.

Simplemachineshaveonlyafewparts.Infact,somearemadeofonlyonepart.Yet,nearlyeverymachinecontainsoneormoreofsimple machines.

Thinkaboutapairofgardenshears.Thesharpedgesofitstwobladesarewedges.Thebladesarealsolevers.Soisthehandle.Thepivotpointonwhichthebladesmoveisascrew.Otherscrewsholdtheparts together.

Simplemachinescanbecombinedinendlesswaystoaccomplishtasks,fromsharpeningapenciltorocketingintospace.Buteachsimplemachinealsohelpsusdoworkallonits own.

ACloserLook

Ascrewwithwiderspacesbetweenthreadswillrequiremoreforcebuttakelesstimeto move.

lessforce,more time

moreforce,less time

threads

Whenyouturnthescrewdriver,thescrewredirectstheforceforwardsoitgoesintothe wood.

TheTurnoftheScrew

Ascrewisaneatlittlemachine.Thoseridges,orthreads,thatcurlaroundareallconnected.Theyformasinglerampthatwrapsaroundarod.It’slikeatinyspiralslide.Thatspiraliswhatmakesascrewdoits job.

Thinkaboutwhathappenswhenyoutwistascrewintoapieceofwood.Youplacethetipofascrewdriverintotheslitinthetopofthescrew.Youturnthehandle.Thattakessomeeffort.Thiseffortprovidestheforceneededtodrivethescrewintothe wood.

Whenyouturnthescrewdriver,youdirecttheforceinacircle.Thescrewdrivertransfersthisforcetothescrew,whichalsomovesinacircle.Butthensomethingveryinterestinghappens.Thescrewchangesthedirectionoftheforce!Asthescrewturns,itchangesforcethatgoesroundandroundintoforcethatgoesstraight forward.

That’sthewholepointofascrew—itredirectsforce.Witheachturnofthescrewdriver,anotherthreadmovesforwardandcutsintothewood.Andoncethescrewisintight,itstaysthatway.Frictionbetweenthethreadsandthewoodholdthescrewwithafiercegripthat’shardtoloosen.So,canyouremoveascrew?Sure,butdon’ttrytopryitoutwiththeclawofa hammer.

Thewaytoremoveascrewistosimplyturnthescrewdriverintheoppositedirection.Thescrewchangesthecirculardirectionoftheforce.Exceptthistime,thescrewredirectstheforcestraightbackwardinsteadof forward.