Problem

Youandafriendarehelpingtobuildadoghouse.Thewoodenboardsarecut.Theholesaredrilled.Thereis justonethinglefttodo.Youhavetoconnecttheboardstotheframe.Yougrabascrewdriver,somescrewsandgoto work.

Thefirstturnofthescrewiseasy.Butthenitgetshardertoturn.Youholdthescrewdrivertightly.Youstraintoturnthescrew.Uhhhh!Grrrr!Afterstruggling,thescrewisstillstickingout.YourdogOllietiltshishead.Hemustbewonderingwhat’sgoingon.Youarewondering, too!

Solution

Guesswhat?Yourfriendishavingamucheasiertime.She isputtinginherthirdscrew.Youaskher.“Whyareyourscrewssoeasytoturn?”Shelooksatyouandsmiles.“IguessI’mjuststrongerthan you.”

“No,really.Ourscrewdriversarethe samesize.Theholesarethesamesize.Eventhescrewsarethe same size.Sowhat’sthe difference?”

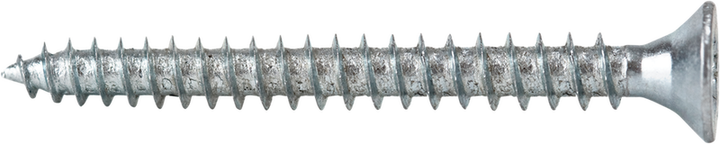

Thenyounoticeit.“Hey,lookatthis.Thethreadsaredifferent.”Theridges,orthreads,arefartherapartthanonyourfriend’sscrews.Yourfriend’sscrewshavealotmorethreads.Andtheyarereallyclosetogether.Thatmustbe it!

Youtryoneofherscrews.Youhavetoturnitalotmoretimes.But,thescrewgoesinfast.“That’smorelikeit!”yousay.“NowIhavetherighttools.We’llhavethisbuiltinnotime.”“AndOllieisgoingtolovehisnewhouse,”yourfriend adds.

Woof!Woof!Olliethinksso, too.

It's Simple

A screw isasimplemachine.Simplemachineshelpusdojobs.Theyhelpmovethingsfaster,farther,ormoreeasilythanwecanwithout them.

Youprobablydon’tthinkofascrewasamachine . .. Instead,youmightpictureacarorapowertool.Thesemachineshavelotsof parts.

Simplemachineshaveonlyafewparts.Somearemadeofonlyonepart.Nearlyeverymachinehasoneormoresimplemachines.Thinkaboutgardenshears.Thesharpedgesofitsbladesarewedges.Thebladesarealsolevers.Soisthehandle.Thepivotpointonwhichthebladesmoveisa screw.

ACloserLook

Ascrewwithfewerthreadswillrequiremoreforcebuttakelesstimeto move.

easiertoturn,takesmore time

hardertoturn,takesless time

threads

Whenyouturnthescrewdriver,thescrewredirectstheforceforwardsoitgoesintothe wood.

TheTurnoftheScrew

Ascrewisaneatlittlemachine.Thoseridges,orthreads,thatwraparoundareallconnected.Theyformasingleramplikeatinyspiralslide.That’swhatmakesascrewdoitsjob.Trytwistingascrewintoapieceofwood.Placethetipofascrewdriverintotheslitinthetopofthescrew.Turnthehandle.Thattakessomeeffort.Thiseffortprovidestheforcethatdrivesthescrewintothe wood.

Turningthescrewdriver,directstheforceinacircle.Italsotransferstheforcetothescrew.Thescrewmovesinacircle.Butthenitchangesthedirectionoftheforce!Insteadofgoingarounditgoesstraight forward.

So,ascrewredirectsforce.Witheachturn,anotherthreadmovesforwardandcutsintothewood. Frictionbetweenthethreadsandthewoodholdthescrewwithagripthat’shardto loosen.

Howdoyouremoveascrew?Turnthescrewdriverintheoppositedirection.Thenthescrewwillredirecttheforcebackwardinsteadof forward.