Problem

Youandafriendarehelpingtobuildadoghouse.Thewoodenboardsarecut.Theholesaredrilled.Thereisjustonethinglefttodo.Youhavetoconnecttheboardstotheframe.Yougrabascrewdriver,somescrews,andgoto work.

Thefirstturnofthescrewiseasy.Butthenitgetshardertoturn.Youholdthescrewdrivertightly.Youstraintoturnthescrew.Uhhhh! Grrrr!Afterstruggling,thescrewisstillstickingout.YourdogOllietiltshishead.Hemustbewonderingwhat’sgoingon.Youarewondering, too!

Solution

Guesswhat?Yourfriendishavingamucheasiertime.Youaskher.“Whyareyourscrewssoeasytoturn?”Shelooksatyouandsmiles.“IguessI’mjuststrongerthan you.”

“No,really.Our screwdriversarethesamesize.Theholesarethesamesize.Eventhescrewsarethesamesize.Sowhat’sthe difference?”

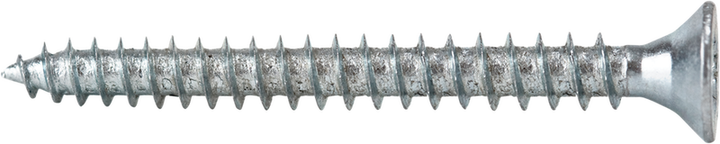

Thenyounoticeit.“Hey,lookatthis.Thethreadsaredifferent.”Theridges,orthreads,onyourscrewsarefartherapart.Yourfriend’sscrewshavealotmorethreads.Theyarereallyclosetogether.Thatmustbe it!

Youtryoneofthosescrews.Youhavetoturnitalotmoretimes.But,theyare easyturns.Thescrewgoesinfast.“That’smorelikeit!”yousay.“NowIhavetheright tools.”

“Ollieisgoingtolovehisnewhouse,”yourfriend adds.

Woof!Woof!Olliethinksso, too.

It's Simple

Ascrewisasimplemachine.Simplemachineshelpusdojobs.Theyhelpmovethingsfaster,farther,ormoreeasilythanwecanwithout them.

Youprobablydon’tthinkofascrewasamachine.Instead,youmightpictureacarorapowertool.Thesemachineshavelotsof parts.

Simplemachineshaveonlyafewparts.Somearemadeofonlyonepart.Nearlyeverymachineismadeofoneormoresimple machines.

ACloserLook

Ascrewwithfewerthreadswillrequiremoreforcebuttakelesstimeto move.

easiertoturn,takesmore time

hardertoturn,takesless time

threads

Whenyouturnthescrewdriver,thescrewredirectstheforceforwardsoitgoesintothe wood.

TheTurnoftheScrew

Theridges,orthreads,thatwraparoundascrewformaramp.That’swhatmakesascrewdoits job.

Trytwistingascrewintoapieceofwood.Putthetipofascrewdriverintotheslitontopofthescrew.Turnthehandle.Thattakessomeeffort.Thiseffortprovidesthe force thatdrivesthescrewintothe wood.

Eachturndirectstheforceinacircle.Italsotransferstheforcetothescrew.Thescrewmovesinacircle.Thenitchangesdirection.Insteadofgoingarounditgoesstraight forward

Witheachturn,anotherthreadmovesforward.Itcutsintothewood.Frictionbetweenthethreadsandthewoodholdsthescrew tightly.

Howdoyouremoveascrew?Turnitintheoppositedirection.Itwillmovebackwardinsteadof forward.