ANewPhilosophy

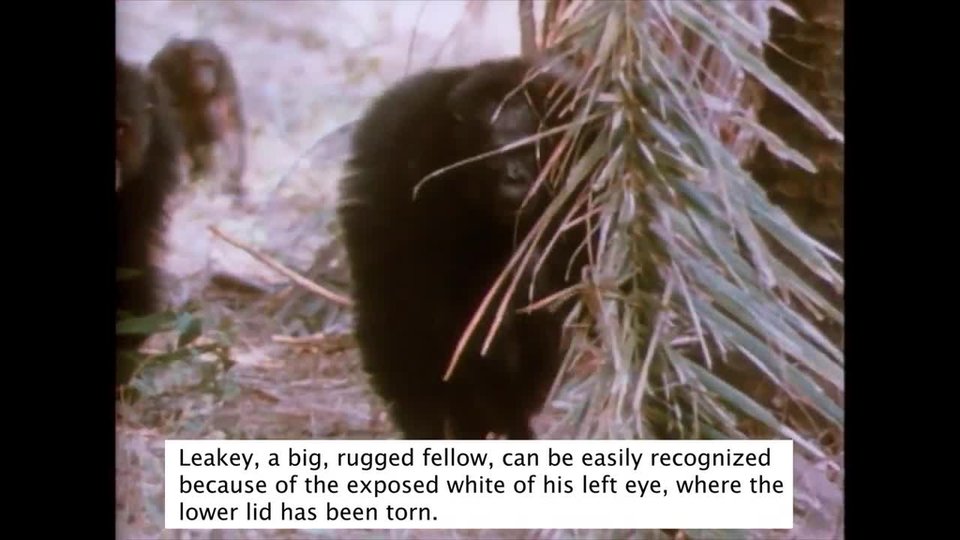

ArthurHuangdesignsbuildingstohavethesmallestcarbonfootprintpossible.WhatisthecarbonfootprintoftheEcoArk? Zero!

Thebuildingrunswithoutreleasinganygas.Thefansandlightsgettheirpowerfromwindandsolarenergy.Theydon’tburncoaloroil either.

SolarpowercapturedduringthedayrunsEcoArk’sLEDlightingsystemsat night.

HuangridesaskateboardmadefromrecycledwasteattheMiniwizofficein Taiwan.

Upcycling

TheEcoArkisjustoneexampleofhowHuangturnstrashintotreasure.Heissurethatmostwastecanbeusedtomakesomethingelse.Thisiscalledupcycling.

Toprovethis,HuangstartedthecompanyMiniwiz.Itsmottois“Itiswisetominimize.”Thegoalistohelppeopleminimizetheircarbonfootprint.How?Byusingupcycled products.

TheSky’stheLimit

Whatcanbemadefromupcycledtrash?Thesky’sthelimit.Miniwizhasdevelopedamaterialtomakewingsforaone-personairplane.Thatreallyputsthe“up”in upcycling!

Whatelsehascomeoutofthe“trashlab”?SunglassesmadefromCDs.Sneakersmadefromupcycled plastic.

Thesesunglassesaremadefromrecycled materials.

Trashpresso

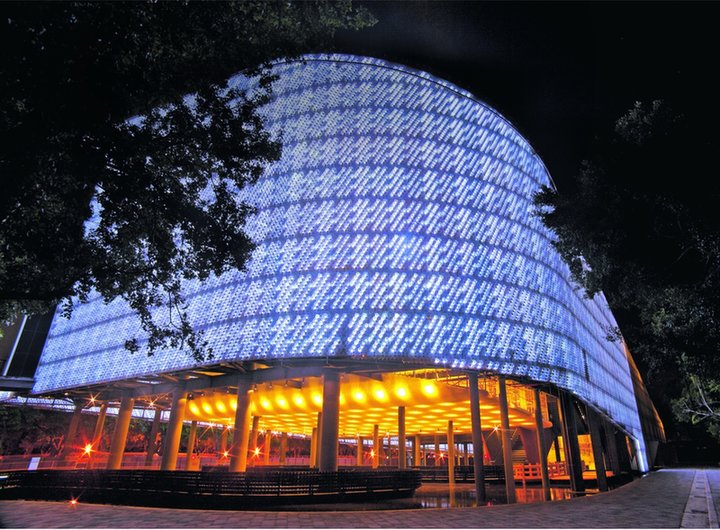

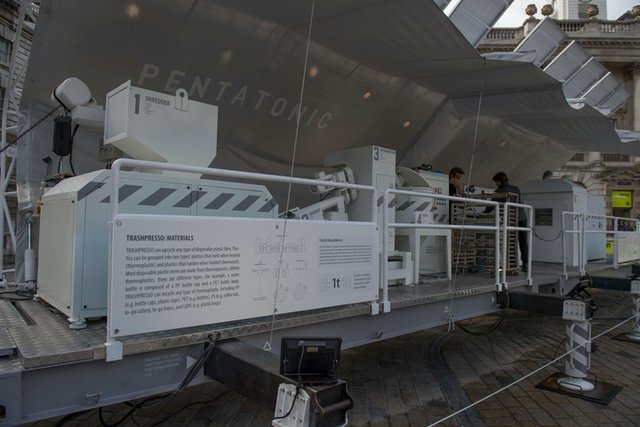

Howdoyouchangeplasticgarbageintoausefulproduct?Miniwizinventedamachineandanewwayofdoing things.

Huangdesignedshoesandtheboxtheycomeinoutof trash.

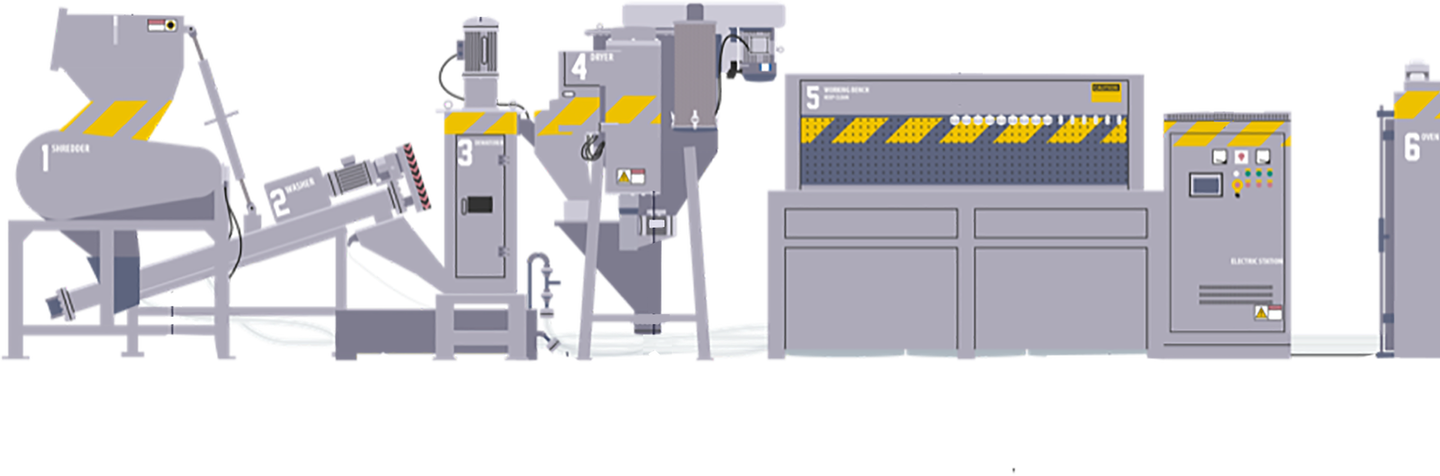

Trashpresso

Trashpressoisanassemblylineofmachinesworkingtogether.First,itshredsplastictrashintoflakes.Theflakesarethenwashed,dried,andplacedintomolds.Theyarepressedandmeltedintoshape.Mostoftheshapesaresix-sidedtiles.Peoplecanusethemtobuildwallsandfloorswithazerocarbon footprint.

Trashpressocangojustaboutanywhere.ThisallowsHuangtoeducatepeopleeverywhereaboutplastictrash.Hecanalsoinspirethemtobepartofthe solution.

Trashpresso

SHREDDER

breaksdownplastictrashintotiny flakes.

DEHUMIDIFIER

driesthewet flakes.

WORK BENCH

iswhereflakesareplacedinto molds.

ELECTRICAL STATION

containstheelectricalsystemtomakethemachine operate.

WASHER

cleanstrashtoremove impurities.

WATER PIPINGcarriesdirtywater away.

DRYER

further reduces

moisture.

WATER TANKSstore waterforthe process.

WORK BENCH

iswhereflakesareplacedinto molds.

ELECTRICAL STATION

containstheelectricalsystemtomakethemachine operate.

AIR FILTER

preventsthereleaseoftoxicvaporsthatmightbeproducedduringthemelting stage.

DRYER

further reduces

moisture.

WATER TANKSstore waterforthe process.

OVEN

iswhereflakesmeltintheirmolds,formingfinished tiles.

WATER FILTERpurifiesthewaterandcyclesthewaterbackthroughthe system.

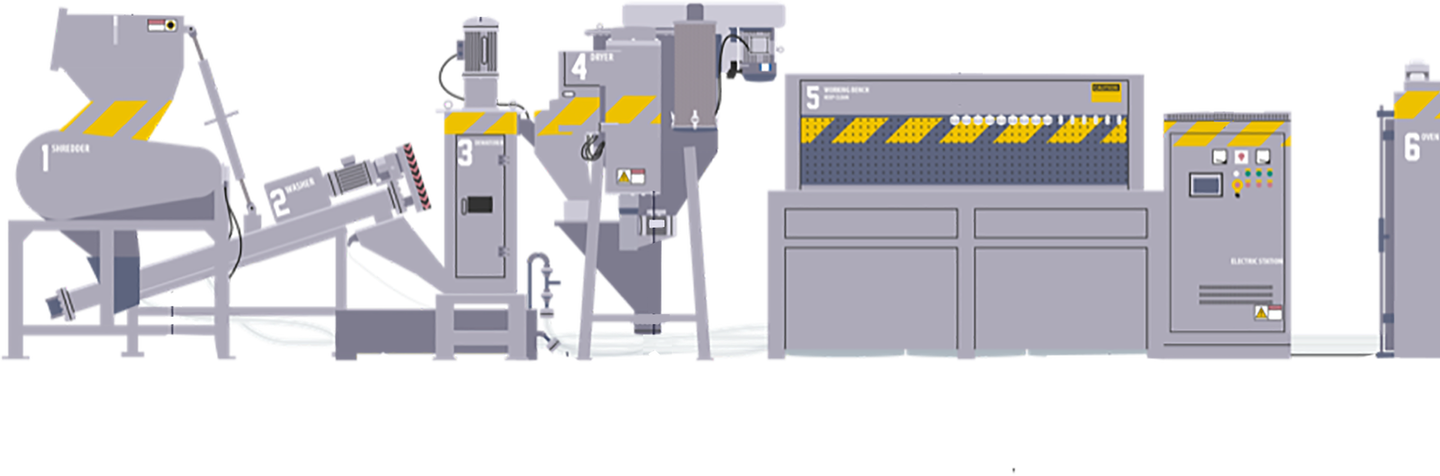

1: SHREDDER

breaks down plastic trash into tiny flakes.

2: WASHER

cleans trash to remove impurities.

3: DEHUMIDIFIER

dries the wet flakes.

4: WATER PIPING

carries dirty water away.

4: DRYER

further reduces moisture.

5: WORK BENCH

is where flakes are placed into molds.

5: WATER TANKS

stores water for the process.

6: ELECTRICAL STATION

contains the electrical system to make the machine operate.

6: AIR FILTER

prevents the release of toxic vapors that might be produced during the melting stage.

6: OVEN

where flakes melt in their molds, forming finished files.

6: WATER FILTER

purifies the water and cycles the water back through the system.

CIRCULARECONOMY

Mosteconomiestodayarelinear.Thismeansresourcesareusedtomakeaproduct.Theproductisusedandthenthrownaway.Thisproduceswasteandpollution.Inacirculareconomy,wasteisusedasaresource.Theproductismadeagainfromanoldone.Oritismadeintoanotherproduct.There’snosuchthingaswasteinacircular economy!

recycle

make

use

reuse

remake